RESULTS

From the research and innovation of AMPERE project comes the new latest-generation photovoltaic panel from EGP’s factory, 3SUN 2.0.

The production will be focused on a new line of latest-generation bifacial photovoltaic modules in Hetero Junction Technology (HJT). The new module is produced by following three stages of production line development:

The first, underway in the second quarter of 2018, calls for the creation of a new assembly line of crystalline cells for the production of panels with bifacial architecture, with a maximum production capacity of 80 MW/year.

The second moves on to the installation of a new production line of HJT cells, operational in the first quarter of 2019, with a maximum production capacity of 110 MW/year.

In the third and final stage, the production capacity of the HJT line will double, up to 200 MW/year, in the third quarter of 2019, which could reach 250 MW/year, with future optimisations.

The factory will work in a continuous cycle, 24 hours a day, 365 days a year, and will see the production, at the end of the technological reconversion, of roughly 1,400 photovoltaic panels a day for a total of about 500,000 panels a year.

MODULES

One of the first Ampere results concern the manufacturing, at 3Sun production site, of a glass-glass module with 72 heterojunction bifacial cells configuration. The certificated output power results in 389 Wp.

The module test has the scope to proof the technical capability of 3SUN production line to target one of the technological goal of Ampere project, specifically to produce bifacial modules with output power of more than 400Wp. The final goal will be reached thanks to the realization at the 3SUN production line of bifacial heterojunction solar cells with an average conversion efficiency of 23.5%.

CELLS

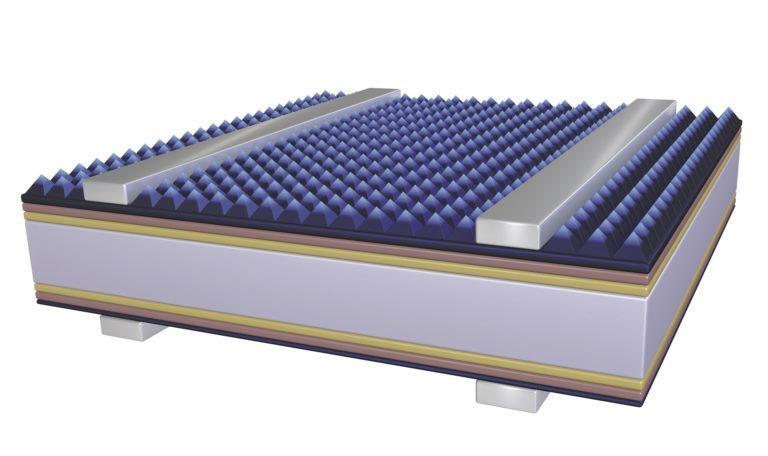

Bifacial n-type Heterojunction solar cell: TCO/ n_aSi:H/ i_aSi:H/ n-cSi / i_a-Si.H/ p_aSi:H/TCO.

Within AMPERE project the heterojunction technology reaches new heights with cells close to 24% efficiency obtained on the industrial pilot line of CEA based at INES

CEA -INES have reached a new record of conversion efficiency produced on Meyer Burger industrial equipment (2400 cells per hour). The yield was certified at 23.9% over the entire surface of a standard size cell (244 cm²) with metallization performed